Diagnostic Trouble Codes or OBD2 Trouble Codes are the codes that a car’s OBD system uses to notify you about an issue within the vehicle’s operation. Each code corresponds to a fault detected in the car. When the vehicle detects an issue, it will activate the corresponding trouble code. These codes are applicable to all diesel-engine based vehicles including Audi VW Ford Citroen Peugeot Renault Dodge GMC GM Mack Chrysler Mopar Dorman Jeep Volvo DAF Iveco Cummins Duramax Isuzu Mercedes-Benz Porsche Land Rover Mazda Perkins Komatsu Caterpillar CAT Perkins John Deere and Toyota but the method of repairing or fixing these issues may differ depending on the make and model.

When your diesel-powered vehicle experience a malfunction in the “A” designation of the electrical circuit of a diesel particulate filter (DPF) pressure sensor, the trouble codes shown by the Powertrain control module (PCM) will indicate towards different issues depending upon the trouble codes but all codes will have the problem with a common equipment i.e.: Diesel Particulate Filter Pressure Sensor.

When you encounter any problem with the DPF sensor, you might receive any of the following codes for the reasons such as DPF sensor is faulty, giving bad readings, circuit is too high or low etc.

P2452 DPF Diesel Particulate Filter Pressure Sensor A Circuit

P2453 DPF Diesel Particulate Filter Pressure Sensor A Circuit Range/Performance

P2454 DPF Diesel Particulate Filter Pressure Sensor A Circuit Low

P2455 DPF Diesel Particulate Filter Pressure Sensor A Circuit High

P2456 DPF Diesel Particulate Filter, Differential Pressure Sensor, Implausible Signal

However, if the sensor is not replaced timely, it will eventually fail and when it fails, PCM can trigger the following codes in addition to the above or sometimes it could be triggered the same time as these codes show and mean that whole DPF system has failed to work properly, so basically it means that one part of the system’s failure can cause whole system to fail.

P2462 DPF Diesel Particulate Filter Pressure Sensor B Circuit Intermittent

P2463 DPF Diesel Particulate Filter Restriction Soot Accumulation

P2464 DPF Diesel Particulate Filter Differential Pressure Too Low Bank 2

P2465 DPF Diesel Particulate Filter Differential Pressure Too High Bank 2

In this blog, we will discuss in detail, what is Diesel Particulate Filter Sensor, Where it is fitted, What it does, Why it fails and how we can fix the failure.

Diesel Particulate filter is basically a soot trap that collects carbon particles from diesel engine exhaust emissions. Under heavy acceleration, black smoke emitting out of the exhaust is largely attributed to the soot. DPF is located in a steel inline exhaust housing and look quite a lot like a catalytic converter and you will find it mounted much closer to the engine before NOX trap. This closeness from the engines helps the DPF to heat up faster and subsequently burn off the soot particles much more quickly. Small particles and other exhaust gas compounds can easily flow out but the large particulate matters are too big to escape so is trapped within the DPF.

Typically, a multi-layer ceramic technology is commonly used to develop a DPF application sensor called Cordierite. Though, Cordierite is inexpensive and has excellent filtration properties but its problem of getting over-heated with high temperatures is what makes it susceptible for malfunctioning in the vehicles equipped with passive DPF systems. The core of a DPF is the filtration element so a wide variety of other elemental compounds such as paper fibers, metal fibers, silicone wall fibers and other ceramic fibers are used by DPF to trap large soot particles and allow the engine exhaust gas to flow. The more soot is accumulated, the higher the exhaust pressure and after an exhaust pressure has reached to a certain level and adequate amount of soot is accumulated, it needs to be regenerated.

On a properly functioning vehicle, regeneration will occur approximately every 500 miles but this is very substantially dependant on the vehicle and driving conditions. PCM is programmed to inject diesel exhaust fluid into exhaust at certain intervals to increase the exhaust temperature and burn the soot particles.

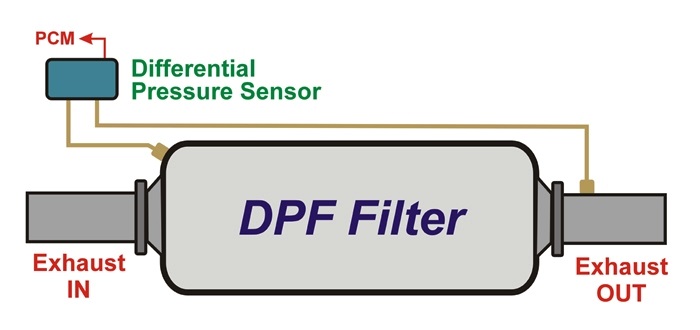

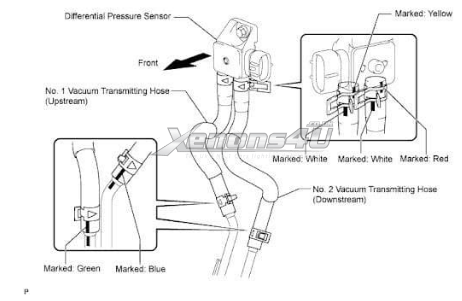

When the calibrated number of regenerations is reached, the cumulative current readings are then used to determine the amount of soot concentration in the exhaust gas which in turn determines the collection efficiency of the diesel particulate filter (DPF). DPF pressure sensor is located in the engine compartment but away from the DPF. Silicone hoses connected to DPF pressure sensors and DPF are used to monitor the exhaust back pressure as it enters DPF.

If the PCM detects any deviation of exhaust pressure condition from that of manufacturer’s specification or DPF pressure sensor A exceeds from the programmed limitations, PCM will store a P 2453 error code which must be addressed immediately to avoid any potential damage to the engine or fuel system.

Symptoms

You will observe the following symptoms with malfunctioning DPF pressure sensor

- Reduced engine performance

- Emission of excessive black smoke from exhaust

- Increased engine temperature

- Higher than normal transmission temperatures

Possible causes

Following are the possible causes for this error code to set on PCM

- Clogged DPF pressure sensor tubes / hoses

- Faulty DPF pressure sensor

- DEF reservoir may be empty and needs to be refilled

- Improper Diesel Exhaust Fluid

- Improper or inactive DPF regeneration

- Open/ short circuit in DPF pressure sensor A circuit

Diagnosis

Before delving into the manual inspection and trying different options, it would be sane to first check technical service bulletins (TSBs) for your particular vehicle. It is possible that your issue might be a known issue to a manufacturer with an easy fix so you can save your money and time spent otherwise.

To perform a diagnostic run you will need:

- A diagnostic scanner

- A manufacturer’s service manual

- Digital voltmeter/ohmmeter / infrared thermometer

You can start your diagnosis by first checking the wirings for any damage that are routed near exhaust hot components and sharp edges. Test alternator output, check the battery and its terminals ends.

Connect the DTC scanner and retrieve all stored error codes and freeze frame data. Write down this information to check later as a reference. Clear the codes and test drive the vehicle.

If the supply lines are intact and the sensor is also operational, check the system circuits and immediately replace or repair open or shorted circuits. Remember to disconnect all the related controllers before testing resistance with the DVOM.

In addition to above, you can also perform following diagnostic and physical checks:

- Clogged sensors ports/ tubes

- Melted or cracked DPF pressure sensor hoses – if replaced, they need to be rerouted after replacement.

After doing proper inspection and if there is no damaged hoses, connectors related to DPF pressure sensor, we firstly recommend to replace sensor itself as in mostly cases it solves the issue.